Paid content

Aluminum: high carbon emissions, but high green potential

Aluminum manufacture puts sizeable strain on the environment. But by using green energy and larger proportions of scrap material, this durable and recyclable light metal can be produced far more sustainably in carbon emissions terms. Griesser of Switzerland is leading the way within its sector in using low-carbon aluminum manufactured in Europe for its solar shading products, as part of its overall endeavors to be climate-neutral in its business activities.

Aluminum manufacture puts sizeable strain on the environment. But by using green energy and larger proportions of scrap material, this durable and recyclable light metal can be produced far more sustainably in carbon emissions terms. Griesser of Switzerland is leading the way within its sector in using low-carbon aluminum manufactured in Europe for its solar shading products, as part of its overall endeavors to be climate-neutral in its business activities.

Aluminum holds the firmest of places in the architecture of today. For solar shading solutions in particular – venetian blinds, rolling shutters, facade awnings and more – this light metal has truly proven its worth. Its durability, its corrosion resistance (which makes it highly weather-resilient), its low weight, its further properties that make it especially versatile in design terms and its recyclability all make aluminum an excellent choice of material for facade applications.

For all its many advantages, though, the use of aluminum in buildings and architecture also brings environmental challenges: the mining of the bauxite required; the large amounts of energy consumed in the metal’s manufacture; and the fused-salt electrolysis process involved, which generates not only substantial carbon dioxide (CO2) emissions but also perfluorinated hydrocarbons or PFCs, which are particularly hazardous in climate care terms.

With its excellent recyclability, aluminum fits particularly well into the circular economy, and has the potential to be one of tomorrow’s leading building materials. It still has a long road ahead, however, to achieve such stature. Too much new aluminum is still being manufactured worldwide; and much of this is still largely being produced using fossil energy sources. Changing this will require not just the ideals of motivated entrepreneurs, but also appropriate political action that forces the adoption of a more sustainable approach.

In times in which climate policy concerns look set to take a back seat to the more pressing issues of both real and tariff wars, and the relevant legal initiatives are being shelved or even abandoned, it is all the more essential that our society should not lose sight of protecting the climate and should assume its own responsibility for doing so. Particular attention should be paid here to those sectors and companies that produce especially high levels of CO2 emissions in their activities. This includes the aluminum industry, which is responsible for significant CO2 emissions due to the electrolysis process used in metal production (with a large part of such carbon emissions generated indirectly, through the use of fossil fuels at the power plants providing the high volumes of electricity required).

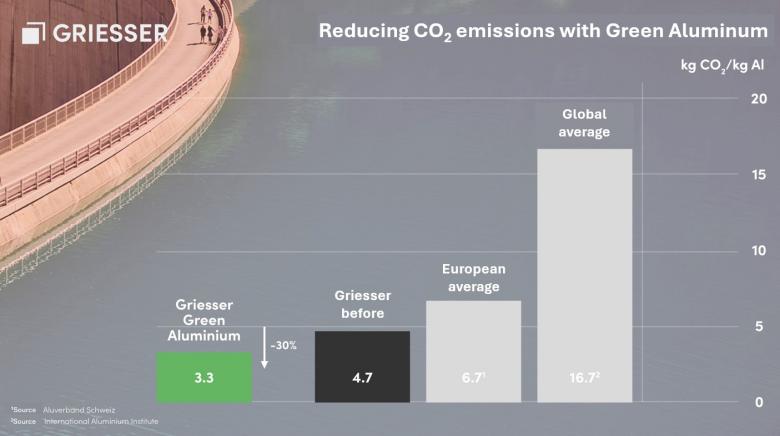

China is the world’s biggest manufacturer of primary aluminum, accounting for some 60 percent of the global total. Most of the country’s output is produced using coal-based energy. And, as a result not least of such high fossil fuel use, the current global average CO2 emissions per kilo of aluminum produced amount to 16.7 kilos. Thanks to more sustainable metal manufacturing and energy generation methods, however, the primary aluminum produced in Europe currently makes an average carbon footprint of just 6.7 kilos of CO2 emissions per kilo of aluminum made.

While the building sector is still far from practicing climate-conscious construction industrywide, more and more companies within it are also setting themselves sustainability goals that include clearly defined reductions in their emissions over time towards a net-zero objective. Griesser is one of them. The Swiss-based manufacturer of solar shading solutions is a pioneer within the industry that has long had its climate ambitions fully integrated into its broader strategic goals.

In the company’s 143-year history, aluminum has been playing a major role for several decades now. “We originally manufactured our products from wood,” Griesser Group CEO Urs Neuhauser confirms. “But we recognized as early as the end of the 1940s that aluminum offered a wide range of benefits in material terms. And today, aluminum dominates our Griesser product world.”

As was to be expected, its intensive use of aluminum has impacted adversely on Griesser’s corporate carbon footprint. Among the categories of emission sources tracked, i.e. materials, energy, transport & mobility and waste disposal, the most of its CO2 emissions by far – 87 percent – are generated in the materials field. And within this category, 78 percent of such emissions derive from aluminum.

All of this makes the full decarbonization of Griesser’s business activities by 2050 all the harder to achieve. “On the plus side, though, our use of aluminum gives us the greatest lever for substantially reducing our carbon footprint,” CEO Neuhauser points out. “And this is why we are prioritizing our actions here, and are looking in this area in particular for the solutions we need.”

In the past, the aluminum used by Griesser in its production of solar shading solutions consisted 64 percent of primary aluminum and 36 percent of pre- and post-consumer scrap. The green aluminum which is now being increasingly used, by contrast, consists 65 percent of pre- and post-consumer scrap and only 35 percent of primary aluminum. This enables the company, which is active throughout Europe, to lower its CO2 emissions per kilo of aluminum used to 3.3 kilos, a substantial reduction of up to 30 percent.

To do so, Griesser is working with two Scandinavia-based suppliers which offer certificated low-carbon aluminum. The arrangement delivers further environmental benefits, too: the primary aluminum involved is manufactured within Europe using renewable energy (hydro and wind power) and advanced production technologies, which combine to entail CO2 emissions that are up to five times lower than they would be with traditional coal-intensive manufacture.

To date, Griesser’s use of green aluminum in its manufacturing processes has been limited to its window shutter product range. “Our window shutters use by far the most aluminum in their manufacture, which is why we have focused our initiative here,” Urs Neuhauser explains. “The challenge we face at present is that the volumes of green aluminum available are too small for us to switch to it entirely and reduce our carbon footprint even more. So we’ve had to adopt a more gradual approach instead.”

Product manufacture using green aluminum is currently more cost-intensive than the use of new aluminum would be. But none of this extra expense is felt by the customer. “The additional costs are not passed on,” Urs Neuhauser confirms. “We absorb them ourselves, through efficiency enhancements such as optimizing our manufacturing processes to reduce production waste, or by redesigning our products to use less aluminum while retaining all their top quality.”

While solar shading solutions may not be the first thing homeowners consider when they are seeking to build or renovate their home to optimize its energy use and minimize its CO2 emissions, these items can play a major part in lowering energy consumption. And if they are also sustainably manufactured, such solutions will have an even greater positive impact on the building’s carbon credentials.

It’s something Griesser’s customers are coming to notice and appreciate, too. “The demand for sustainable products in the solar shading segment is clearly – if slowly – growing,” Urs Neuhauser observes. “But a lot more sensitization is still required.”

Of equal importance, though, is moving matters forward in the sector as a whole. “The simple fact is that if we are to meet and master the challenge of the climate crisis, we will need not just individual initiatives but the joint efforts of us all. And this is why it is so important to us at Griesser to generate an industrywide momentum that should help us collectively tackle climate change.”